Bolting Process Monitoring on Non Shut Off Tools TMS Bolting Process Monitoring on Non-Shut-Off Tools – Demonstrate how to set up and achieve torque-controlled results using the torque substitute value, the Torque or Timer feature notification, and the data logging feature with a wireless torque transducer on non-shut-off tools. […]

Category Archives: Technical

TMS Bolting process monitoring with auto shut off tools Demonstrate the data logging feature with a wireless torque transducer on auto-shutoff tools. ZIPPTORK’s TTES Series Wireless Shock & Impact Proof Torque Transducer: Advanced Torque Measurement with Durability and Precision – Designed for torque tightening process monitoring with fully-featured data […]

Background: Clutched vs. Oil Pulse Tools When selecting an assembly tool, engineers typically compare clutched-type tools and oil pulse tools. Each has advantages and drawbacks: Clutched tools Torque Range: Up to ~400 in-lbs (33 ft-lbs). Effective for low to medium torque, but requires torque arms above ~80 in-lbs due to wrist […]

In precision assembly, every fastening operation must deliver consistent torque to guarantee product safety, performance, and quality. Over time, however, power tools drift out of tolerance due to wear, vibration, or repeated impact. Without routine verification, this drift can compromise joint integrity and increase the risk of product failure. ZIPPTORK’s wireless rotary torque sensor provides […]

ZIPPTORK’s torque controller upgrades a standard pneumatic impact wrench into a torque-controlled fastening tool delivering ±10% to ±15% accuracy (joint-dependent). It closes the historical gap between “roughing” with impacts and “controlling” with expensive, high-maintenance pulse or DC tools. Paired with an integrated wireless torque transducer, ZIPPTORK captures every tightening—time, torque curve, angle, and result—so you […]

Precision torque control is a cornerstone of success in industries that demand impeccable assembly quality. Pneumatic tools such as air impact and pulse wrenches are often favored for their durability, speed, and power. However, achieving accurate and consistent torque results with these tools can be challenging. ZIPPTORK’s torque controller provides an innovative solution, offering unparalleled […]

Precision, reliability, and efficiency are non-negotiable in today’s fast-paced manufacturing environments. Torque tools are pivotal in assembly lines, ensuring components are tightened to exact specifications. However, traditional torque monitoring systems often fall short when exposed to vibrations, shocks, and other operational challenges on the assembly floor. ZIPPTORK’s anti-vibration & shockproof wireless torque transducer addresses these […]

Torque control is critical in various engineering applications, from manufacturing to automotive engineering, where precision and reliability are essential. Understanding the variables affecting torque control is crucial for ensuring mechanical systems function correctly and safely. Below are some of the critical variables that influence torque control. 1. Type of Fastener The type of […]

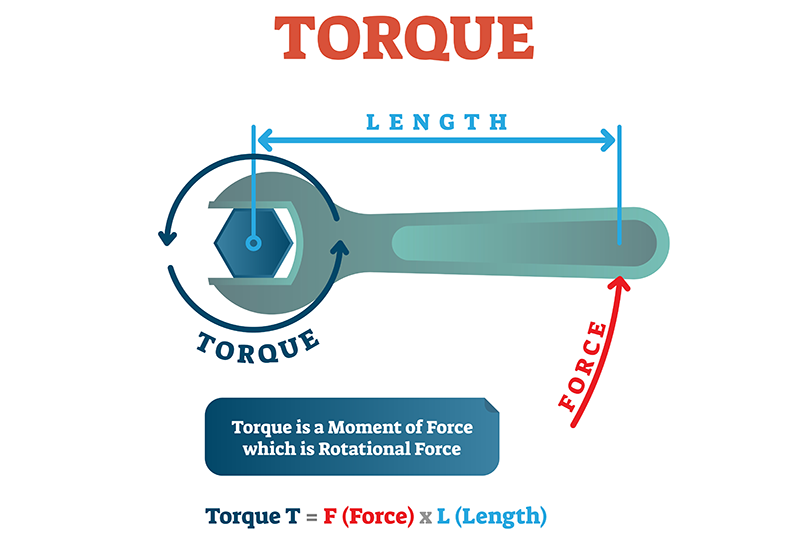

Torque, often called the moment of force, measures how much force acting on an object causes that object to rotate. It is critical in many engineering and mechanical applications, from automotive engineering to machinery design. Understanding how to measure torque accurately is essential for ensuring proper functioning and safety in these applications. Below are […]

Determining the correct torque specification for a particular application is crucial in ensuring mechanical assemblies’ proper functioning and longevity. Incorrect torque settings can lead to component failure, safety hazards, and costly repairs. Below is a detailed guide on determining torque specifications for various applications. 1. Understand the Components Involved Before determining the torque […]