ZIPPTORK Bolting Technology – Bolt Load Control of Threaded Fasteners

To meet the Industry 4.0 trend in industrial development, our company has introduced a full range of patented bolt-tightening products that provide a cost-effective solution for the industry. Bolting of threaded fasteners is affected by many factors, such as the softness of the material of the fasteners (bolts, nuts and washers) and the surface roughness of the fasteners to be tightened, the influence of bruises or oil contamination on the threads during the process, and the difference in the structure and quality of the tools used, all of which make it difficult to control accurately and effectively.

Furthermore, for the most essential purpose of bolting works ~ the clamping force applied to the bolted joint, most of the industry can only control the clamping force of the bolt load by ultrasonic sensing & bolting technology. Some applications even require monitoring of the bolted joint status after bolting and real-time notification when abnormal conditions occur. For this purpose, ZIPPTORK has developed a series of bolt-load control technologies to provide the ultimate solution for threaded fastener tightening work, fully meeting the requirements of Industrial Internet of Things (IIoT) applications.

Sensing Bolt & patented anti-vibration Sensing Washer for bolt load control & monitoring

It is ideal for all kinds of bolt-tightening operations that require precise control of clamping force and continuous monitoring of the bolted joint status. The patented anti-loosening design and ease of use make it a more advantageous alternative to conventional ultrasonic sensing & bolting technology in mainstream applications, offering greater cost-effectiveness.

Patented Bolt Load Transducer

It can be used with any brand of manual, pneumatic, or electric torque tools to directly control and display the clamping force at the bolted joint generated by the applied torque at that time, and to collect relevant data. It overturns the traditional method of controlling bolting torque with torque tools, instead directly measuring the clamping force in the bolted joint, thereby improving the quality of bolting operations. A new era of “Bolt Load Wrench” is to come!

Ideal for critical bolted joints where bolt load control is important & bolted joint status monitoring is required

The Ultimate Solution of Bolting Technology

Sensing Washer with functions of anti-loosening for controlling bolt load and monitoring the bolted joint status

- What is different from the past products or current market products?

Currently, the following methods are commonly used to test the clamping force in the market:- Ultrasonic inspection method: This method is time-consuming, labor-intensive, and expensive.

- Wired sensor bolt – This test method is wired, challenging to achieve wirelessly, and expensive.

- Load cell: This inspection method is wired, challenging to implement wirelessly, and expensive.

Clamping force control is only for connecting the sensor to the PLC or other display device via a wire. The layout of the bolt load sensor in these methods is laborious and time-consuming, and the clamping force sensor lacks an anti-loosening design and a bolting sequence control function.

- Our company has been in the field of pneumatic tools for more than 40 years, and has been dedicated to the research and development of bolting technology for decades.

However, in bolting operations, torque control is not the most accurate technology; bolt load (clamping force) control is the ultimate and most precise method. Since bolt load sensors are more expensive than torque sensors, the market is still dominated by torque control. In recent years, customer demand for bolting work and data recording has increased, and there is an urgent need for clamping force control in the market. Therefore, our company has spared no effort to innovate and advance research and development to deliver the best and most advanced clamping force control and monitoring for thread fasteners.

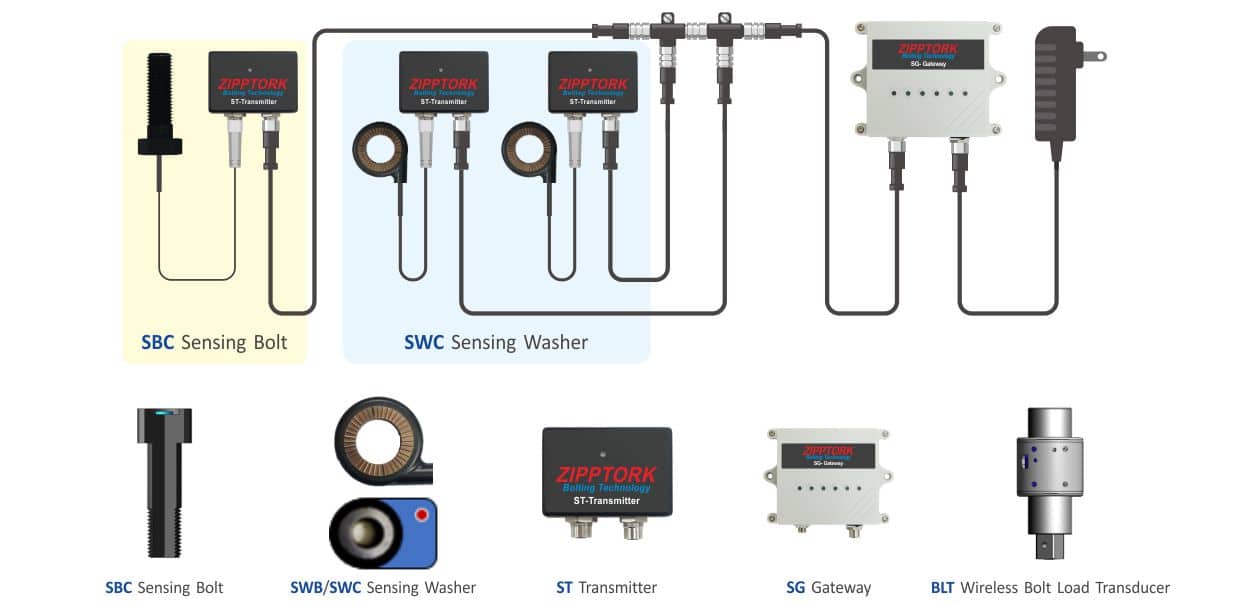

- Due to the difficulty of mass-producing the wireless bolt load sensor, the Sensing Bolt developed by our company at the beginning has been hard to improve yield rates and reduce costs. With our efforts, we have finally created a new generation of Sensing Washers to replace the Sensing Bolts, which have the following advantages:

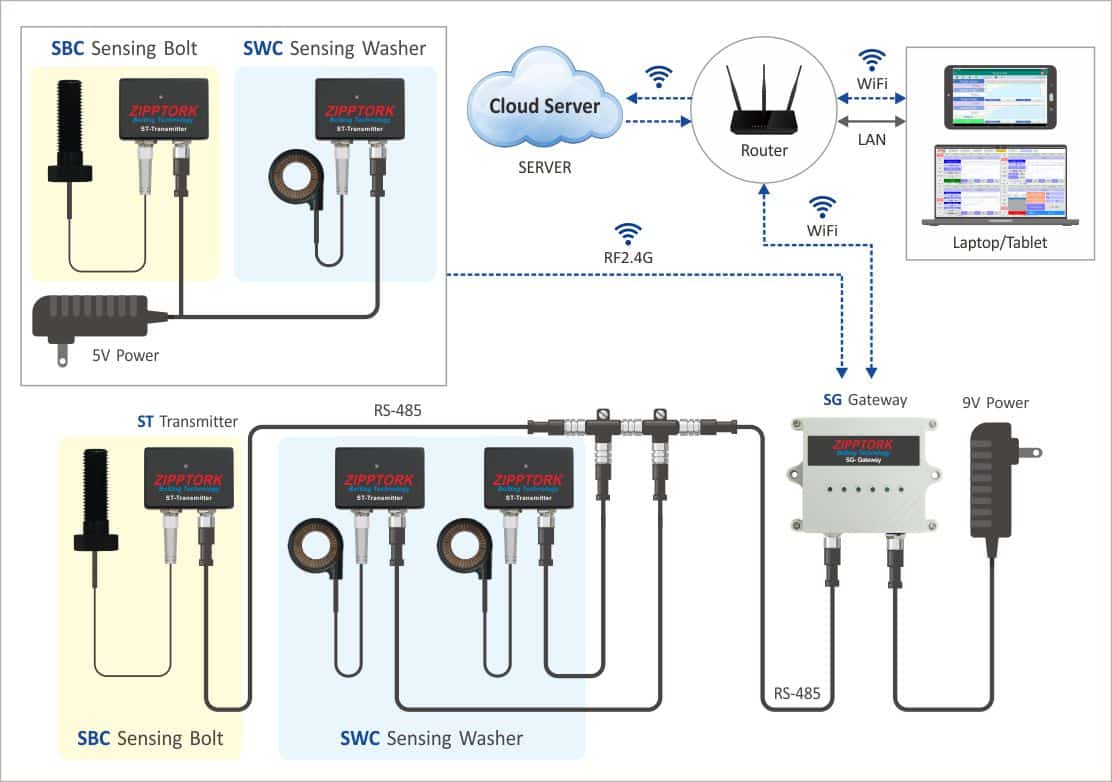

- The Sensing Washer supports both wireless and wired communication. The wireless Sensing Washer is ideal for small magnetic field interference fields – such as the automotive and oil mining industries; the wired induction spacer is suitable for large magnetic field interference fields – such as the construction and bridge industries, and the aerospace industry.

- Low production cost and high yield rate

- Anti-loosening design (the sensing bolt itself does not have one) – this anti-loosening design is patented. In practice, it is easy to carry, install, and operate.

- Higher accuracy and stability than sensing bolts, with dynamic bolt load control accuracy of ±10% and static bolt load control accuracy of ±5%.

- No need to use special or custom-made bolts; use general bolts and sensing washers to achieve the following functions:

During the bolting process:

a) The bolting sequence can be controlled with our innovative controller and tag.

b) Bolt load control

c) Torque equivalent for reference. After bolting,

combined with Industry 4.0-IoT:

a) Bolted joint ( bolt load-clamping force) monitoring

b) Torque equivalent display

c) Clamping force, torque equivalent abnormal alarm - Applicable tools: Any brand of manual, pneumatic, and electric torque tools (static, impact, hydraulic pulse)

- Application: Construction, oil, mining, automotive, aerospace, etc., where clamping force monitoring is required.

- Applicable environment: High magnetic field interference environment, lightning strike environment, etc.

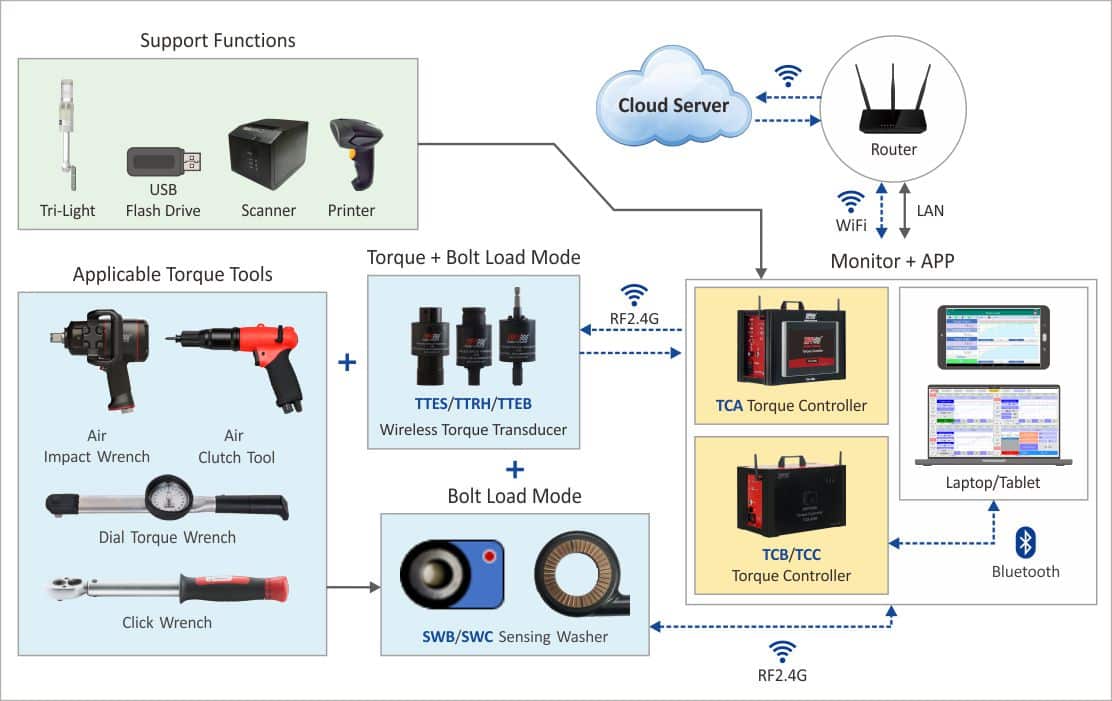

- The application can be used not only with our self-developed controller for clamping force and bolting sequence control, but also as a stand-alone device. The detailed application structure is attached.

ZIPPTORK Bolt Load Control & Monitoring

Anti-vibration Sensing Washer

|

|

Sensing Bolt

|

|

ZIPPTORK Bolt Load Control Technology

Wireless Bolt Load Transducer

| For sensing and controlling the bolt load generated in |

Bolt Load Control Products Application Embodiment

Bolt Load Control During Bolting Process