Current work method:

Using air impact or pulse wrench to tighten up to around 80% of final torque then use torque click wrench to tighten to 100% target torque with torque accuracy within ±5%~±10%

Possible risks on the current work method:

- Torque click wrench does not provide any visual signs or number readings, therefore it’s not possible to know or record the final result.

- Torque click wrench is not reliable as when it clicks, it does not mean the actual torque is within the target torque range

- Operating gestures on the torque click wrench may impact the final tighten result.

Example on the chassis assembly

Target torque range:

30Nm, 60Nm, 110Nm

170Nm, 260Nm, 295Nm

Target torque range:

30Nm, 60Nm, 110Nm

260Nm, 298Nm, 395Nm

460Nm, 650Nm, 750Nm

Recommended ZIPPTORK products

TTAS Static use wireless torque transducer:

TTAS-100 to be used for 30Nm & 60Nm

TTAS-180 to be used for 110Nm

TTAS-250 to be used for 170Nm

TTAS-500 to be used for 260Nm, 295Nm, 298Nm, 395Nm

TTAS-750 to be used for 460Nm & 650Nm

TTAS-1000 to be used for 750Nm

Proposed solution:

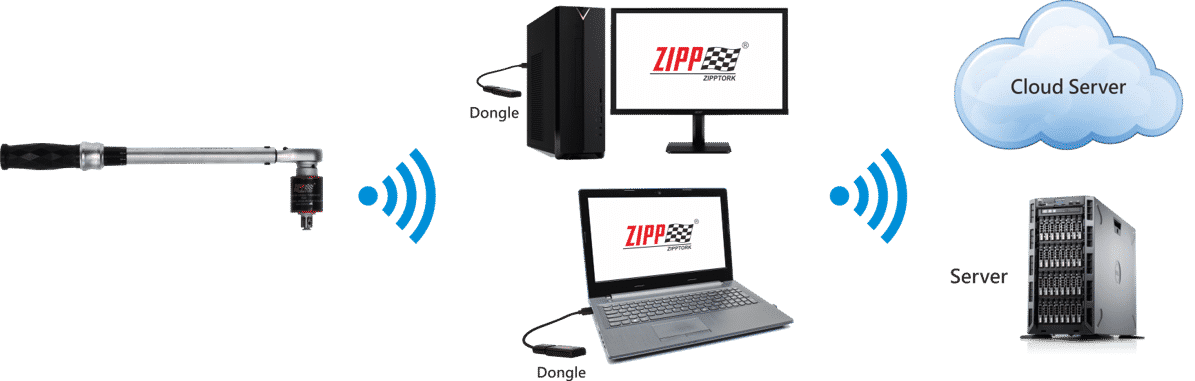

The wireless torque transducer adapt on click wrench will record the final tightened torque and shows the real time torque reading on each of the bolts with angle. Target specification with tolerance can be set up in the software and have all the records stored on the device or upload to the Cloud server.

Additional benefits:

- Prevent untightened bolt and counting the number of tightened bolts.

- Prevent re-hit / re-tighten the bolt with angle monitoring during the process

Advantages:

- Can be easily integrated to the work stations/processes by attach the wireless torque transducer to existing tools

- Cost saving and easy integration solution to enable extra insurances on each bolt tightening tasks while enjoy the benefits of following features from software provided.

- Real time tightening torque and judgement

- Records operator ID and can be controlled by personalize accounts or permissions

- Records work piece serial number

- Records actual torque

- Records tightened result

- Records work time

- Data logging and uploads to preferred Cloud server or destination

- Work parameters like target torque, quantity and tightened angle can be set up in advance to ensure no misses or errors